Great Lakes Dental Technologies leverages new materials and fabrication techniques like 3D printing to increase appliances effectiveness and to create a better experience for patients.

Great Lakes Dental Technologies has fabricated sleep appliances for over 25 years. In that time, fabrication techniques have evolved to take advantage of traditional materials such as acrylic and wires. Optimization of these appliances within the confines of the materials’ characteristics created some uncrossable boundaries. Balancing the qualities of fit, strength and durability, comfort and flexibility, as well as cost has always been a challenge.

The advent of 3D printing in dentistry, or more specifically, the application of additive manufacturing to create appliances rather than models has opened new opportunities for appliance design that were previously impossible.

The Herbst®* sleep appliance is a popular and widely used appliance that is ideally suited for the application of 3D printing technology. Here we discuss two innovative versions of the Herbst sleep appliance – one laser sintered from nylon and another laser melted from chrome-cobalt.

Traditionally, the Herbst appliance fabrication technique features several labor-intensive and skilled steps including bending heavy wire framework for reinforcement, adapting acrylic and thermoplastic for structure, and placement of hardware which is critical and requires skill and experience to perform by hand.

The challenges or limitations include requiring a technician with experience and skill; both in wire bending and acrylic and trimming procedures. A lengthy training time for technicians is typical. Appliance durability is only increased by wire framework or adding acrylic bulk. The added bulk is a deterrent to patient compliance and occupies valuable tongue space. Additionally, the Herbst appliance is still subject to fracture and wear from the destructive forces of bruxism.

Laser Sintering

Laser sintering technology has been around for years. Its application in dentistry is more recent – specifically metal applications in crown, bridge, removable partial denture (RPD) frameworks, and nylon applications in sleep; examples include the Narval and Panthera D-SAD™ appliances. Laser sintering requires a comparatively large capital investment compared to traditional skilled fabrication but will become more common and accessible as the technology matures in the dental space.

The technology allows for digital design of appliances. The laser melts layers from a bed of dry powder, rather than curing layers of liquid resin with light. Laser sintering yields a wider variety of different material properties.

Nylon Laser Sintering

For a Herbst appliance, using laser sintered nylon results in a very thin and comfortable appliance. A nylon “overlay” substructure is created to receive custom Herbst pivot hardware. The advantages include an aesthetically favorable white plastic, an extremely durable and strong appliance that also features uniquely flexible properties.

The nylon Herbst appliance can be made very thin (less than 1mm thick), and it will still be incredibly durable and retentive while maintaining its flexible nature at this thickness. This makes the appliance easier to insert and much more comfortable for the patient. The low-profile design precisely engages the undercuts to enhance retention and fit.

Post-processing of the sintered parts is a significant component of the workflow, and one that should be specially adapted to each type of part being fabricated. Nylon sintered parts require depowdering after removal from the machine. This can be done by hand with a media blasting cabinet. It can also be automated with rough tumbling.

After depowdering, polishing can be accomplished by hand or by a largely automated tumbling process with several media stages. Some dental parts, including most sleep appliances, are well-suited for isotropic finishing. However, some appliances such as splints require a more targeted approach to preserve the critical accuracy of the occlusal contact area.

Metal Laser Sintering

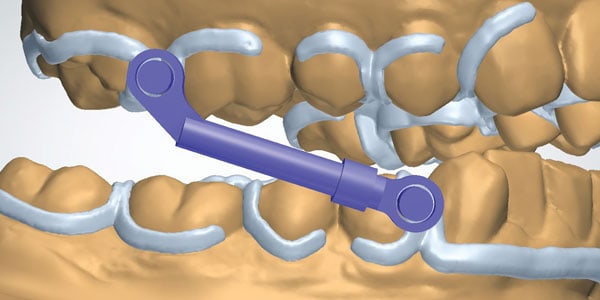

Metal sintering technology allows for a removable Herbst sleep appliance with an entirely metal framework and no added acrylic. Appliance fabrication using metal laser sintering technology relies less on manual technician skill and is extremely consistent.

The Herbst framework is laser sintered in chrome-cobalt to which Herbst pivots are then also laser welded. The metal sintered appliance is very strong and can use an RPD-style skeleton to support the Herbst pivots, reducing the overall bulk and creating the lowest profile appliance possible. Retention is designed like removable partial dentures, with the undercut being engaged precisely.

Experienced technicians translate years of bench experience into the digital design process.

The framework is designed in software, so the clasping is accurate and effective. Hardware placement is simulated in the software to ensure comfort and freedom of movement.

Metal sintering requires significant post-processing. Support structures are created with every part, and then must be removed prior to finishing. Care and effort are taken in the initial stages of design to facilitate the removal of these supports. These parts, like nylon, require an initial rough surface improvement to depowder and prepare for subsequent stages.

Metal sintered parts can be finished by hand, requiring several stages of grinding with a stone wheel to smooth the part sufficiently for polish. The parts can also be efficiently tumbled in a variety of tumbling machines to produce a desirable smoothness. Electro-polishing can also be used as a final polishing stage.

Fabrication consistency is high and appliance records can be kept indefinitely. Design parameters of appliances can be controlled more objectively, and in some cases quantified, creating better communication between labs and doctors. Highly technical elements are reallocated to the digital design portion of the workflow providing opportunities for work to be done remotely. As laser sintering technology becomes more accessible to labs, the main differentiating factor will be the quality of the digital design – anchored by the experience and skill of technicians.

Digital design of appliances is the future of lab work. Leveraging new materials and fabrication techniques pushes the design and appliance effectiveness further forward and creates better diagnostic and therapeutic experiences for patients. Great Lakes Dental Technologies is committed to this pursuit and has sintered it into product development and appliance fabrication operations.

About Great Lakes

Great Lakes Dental Technologies is an employee-owned company, with 186 employee-owners who design, develop, manufacture, and market appliances and products for use in the orthodontic, dental, and sleep and airway markets. Great Lakes is one of North America’s largest orthodontic laboratories and offers more than 4,000 products and services. Training and education on the latest appliance fabrication techniques and equipment is offered online and at the onsite training center at the company’s headquarters.

*Herbst is a registered trademark of Dentaurum, Inc.

Great Lakes Dental Technologies’ Medley Sleep Appliance offers personalized advancement options for ultimate patient comfort. Read more about it here: https://dentalsleeppractice.com/industry-news/great-lakes-now-offers-the-medley-sleep-appliance/