Panthera Sleep blends design, 3D printing, material, and knowledge to its oral appliance therapies.

by Diane Robichaud, Panthera Dental co-founder, Dental Technician

by Diane Robichaud, Panthera Dental co-founder, Dental Technician

Change is constant. New designs, materials, and manufacturing methods are shaking things up for oral appliance therapy. Comfort, outcomes, and durability have improved. Let’s explore Panthera Sleep’s contribution to this transformation.

Design Philosophy

Oral Appliance (OA) design philosophy must come first before considerations of materials and manufacturing methods.

At Panthera, the design philosophy is about reducing forces on teeth and joints, mitigating risks of side effects, and maximizing patient comfort. Every OA decision originates from this philosophy, starting with selecting the proper retention and titration systems, designing the appropriate bands and plateaus, and carefully measuring the biomechanical impacts of even the smallest change.

The vision is to create the best appliance for each patient. Therefore, we set out to build an industrial platform able to execute this vision at scale without any of the traditional manufacturing constraints.

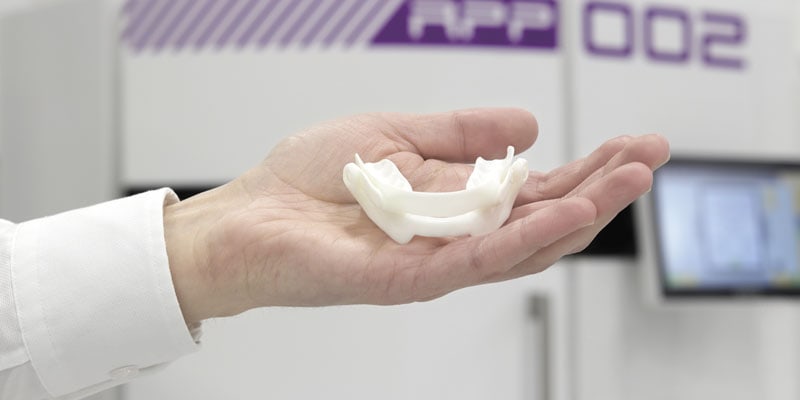

The Dynamic Duo: 3D Printing and Medical Grade Nylon

Nylon has shown tremendous benefits in the medical device industry. Its mechanical properties allow it to be flexible or rigid as needed, for accurate matching to the most complex dentition and undercut retention while being less bulky, stronger, and more durable than traditional materials. Combining this versatility with industrial 3D printing allows us to create any object of any shape and is one of the two keys to creating truly patient-matched appliances aligned with our design philosophy.

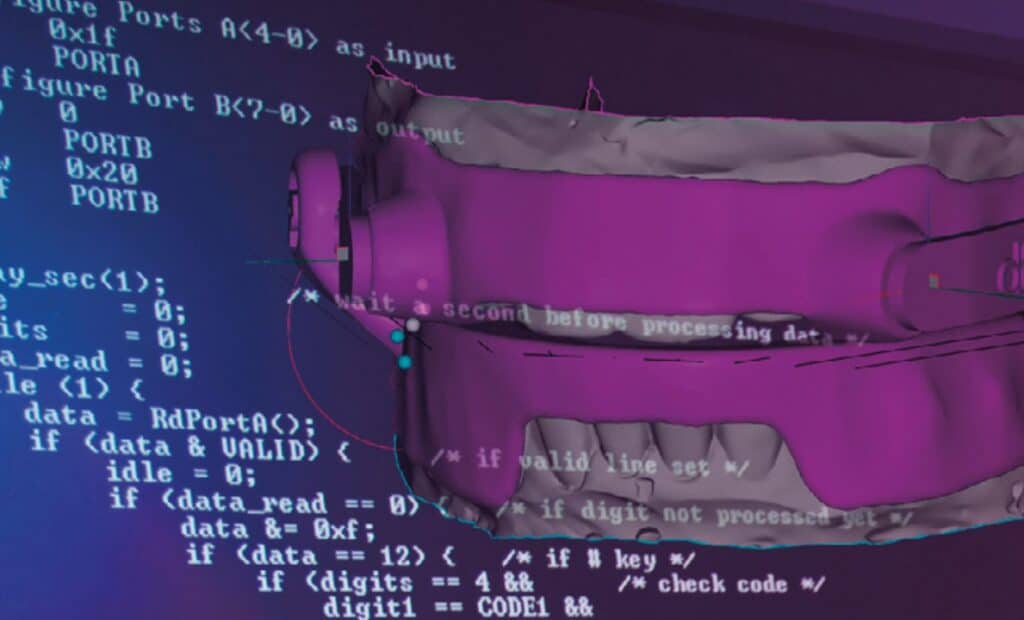

The Software that Powers the Dynamic Duo

The second key is Panthera’s proprietary software, which is purpose-built in-house for the manufacturing of OA. It allows the freedom to execute any design on the CAD side, and for precision, consistency, and speed at an industrial scale on the CAM side. These innovations make the Panthera difference notable.

Blending Design, Manufacturing, and Materials = Quality

Panthera has decades of know-how in the dental world, and is an Industry 4.0 pioneer, combining innovations such as robotics, AI, automation, and 3D printing. Yet quality must always align with innovation, and Panthera’s leadership has engaged the organization with a quality culture from the ground up. Achieving and maintaining over the years the ISO 13485 certification as a medical device manufacturer is evidence of the highest standards for quality management.

The Panthera Whys!

Panthera’s first “why” is the patient. Patients viewing the first-time fit of their OA as comfortable will improve adherence, treatment experience, and satisfaction. Because the patient and their experience matter, design philosophies and manufacturing choices must allow for a no-compromise “Care that Fits” mindset.

Panthera’s second “why” are the providers. Physicians will appreciate the time to treatment, durability, and improvement in adherence. For the dental provider, it is the timeliness, first-time fit rates, and reduced risk of side effects that will minimize problem appointments and, at the end of the day improve profitability. In summary, the blend of design, 3D printing, material, and know-how results in a perfect combination of technology and quality, dedicated to patient care.

For more about digital sleep dentistry and Panthera Sleep appliances, watch this webinar hosted by Dr. Jonathan Ford. https://dentalsleeppractice.com/webinar/digital-sleep-dentistry-panthera-sleep-appliances-and-their-advantages/.